Online sulfur analysis boosts distillation quality

One of the toughest challenges for a petroleum refinery is to select the best combination of components to produce cost-effective, on-spec petroleum products. The goal of petroleum blending is to blend as economically as possible to reduce the octane usage and achieve the desirable boiling point target, while still meeting the required specification. Accurate, online measurement of boiling point and total sulfur provides crucial information to prevent product giveaway and reprocessing, and helps optimise the petroleum blending process.

A laboratory test is a critical part of the measurement process. However, it can be time-consuming, making it inadequate for process control. When processes rely on laboratory testing, they may only get three data points in 24 hours. This lengthy process means that variables can change within the process and impact the accuracy of the measurements.

To achieve minimum product giveaway, it is important to utilise an online analytical method that correlates with the laboratory analysis. This correlation is critical for validating the online results to ensure the final product meets specification. Online analysers that use the same method as the laboratory method are preferred since they reduce errors and bias. This allows refineries to ensure specifications are met to satisfy environmental concerns and target blending requirements.

A boiling point analyser such as the PAC MicroDist can offer real distillation in less than 10 minutes in tight correlation with ASTM D86. They are ideal for certification of atmospheric distillation of light and middle distillate fuels with boiling points in the range of 20 to 400°C. MicroDist detects any of the Group 1-4 fuel types by doing a test distillation in which the new heating profile is set up automatically, minimising delay in the next analysis.

The method is highly precise for determining gasoline boiling point data, and field tests have proven the 50% point to be well within the D86 method limits. This results in better tracking of blending changes caused by component changes since it measures the change in pressure and temperature in the flask and does not require correlation software.

Because of the harmful effects of sulfur emissions on the environment, sulfur content is tightly controlled in fuels for automobiles, aviation, marine vessels, off-road vehicles, power plants and home heating. By correlating with ASTM D5453, an instrument such as the Antek 6200 accomplishes total sulfur detection through pyro-fluorescence, which involves heating the sample to over 1000°C in the presence of excess of oxygen and exposing the combusted material to UV light.

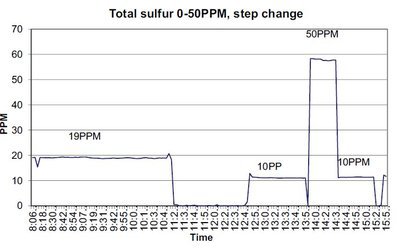

Well-maintained online systems will have a short payoff period and result in optimal product. Because a typical process may only get three data points in 24 hours from the lab, an online analyser that provides a data point every 5-10 minutes is a better solution. With fast results that agree with the lab, the refinery can immediately detect process changes and make corrections with confidence. The immediate feedback facilitates process optimisation around the clock, 365 days a year.

Online analysis provides crucial information to prevent giveaway and reprocessing, and optimise the gasoline blending process. It also ensures specifications are met to satisfy environmental concerns and target blending requirements. Table 1 demonstrates a profitability calculation in the gasoline blender for a boiling point analyser. A return on investment can be obtained in a little over a month.

|

Investment |

$350,000 |

|

Economics |

$300,000/month x |

| Analyser maintenance $/year | $14,160 |

| Net analyser earnings $/year | $3,585,840 |

| Payout, years | 0.1 (payout in 36 days) |

Aquamonix integrates flow monitoring for major gold producer

Instrumentation company Aquamonix has installed a flow monitoring solution for a major...

Magnetic flow meters: Verification and calibration within the process

Magnetic flow meters are often the best solution to measure flows of slurries, sludges and all...

Level measurement in water and wastewater lift stations

Condensation, build-up, obstructions and silt can cause difficulties in making reliable level...