Level measurement in water and wastewater lift stations

Condensation, build-up, obstructions and silt can cause difficulties in making reliable level measurements in lift station wet wells.

Lift stations pump water and wastewater from a lower to higher elevation to compensate for topographical changes. Most processing facilities are fed by gravity flow of the water and wastewater, so in locations where a change in elevation prevents gravity feed, lift stations pump the water to a higher elevation to increase the hydraulic head in order to provide reliable gravity flow into the facility.

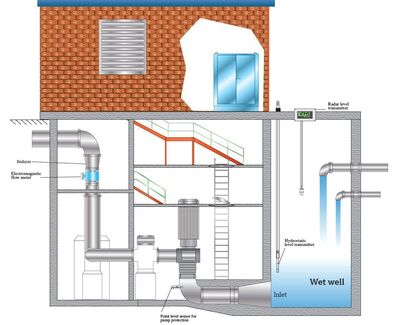

Water level in the lift station wet well or reservoir needs to be monitored to provide input to the pump (Figure 1), which pumps water out when it reaches a pre-determined level. The level measurement also turns off the pump at a minimum level to prevent run-dry damage.

Wet wells can be a difficult environment for instrumentation due to the high humidity and condensation typically present. Heavy coatings and vapours can be found in sewage wet wells, which are capable of coating or corroding mechanical level measurement devices and leaving them inoperable. In these situations, technologies that do not contact the material being measured should be considered.

Historically, level measurement in lift station wet wells has utilised several technologies, including floats, submersible hydrostatic instruments and non-contact ultrasonic instruments. These technologies can be effective when properly selected and maintained, so let’s take a look at each and consider the positive and negative points.

Traditional technologies

Float switches

For decades, float switches have been used for wet well level measurement. The advantages of float switches are low cost and simple operation. Typically, two or more floats are used, with one acting as a high-level pump-on and another float acting as a low-level pump-off indication. While floats have advantages in cost and simplicity, they can fall short in several ways.

Depending on the type of float, the linkage or cable tether can foul or hang up. Floats can sometimes also leak causing a loss of buoyancy. In wastewater applications, build-up on the float can cause it to sink. When using floats for wet well applications, regular maintenance is extremely important to ensure proper operation.

Level switches are often used as a high-level back-up for a continuous level transmitter to indicate if the level reaches a point where the well is close to overflowing. Since the high-level switch is only reached in ‘upset’ conditions, floats work fairly well as a high-level switch.

Submersible hydrostatic level instruments

In contrast, submersible hydrostatic level transmitters operate on the head pressure of the water. A diaphragm in the transmitter is subjected to the water column on one side and referenced to atmosphere on the other side. Increases and decreases in level deform the diaphragm and cause changes in a capacitance bridge circuit, which is then converted to an output.

Submersible transmitters have several advantages. Firstly, they can be pre-selected for the applicable range of level measurement: for example, the transmitter may be ranged from 0 to 10 m of water, and since they are pre-ranged, no calibration is required. Submersible transmitters also have no moving parts to hang up or wear out.

Still, it is important to make sure the diaphragm does not become clogged with silt or other solids as clogging will affect accuracy. A heavy build-up can prevent the diaphragm from reacting to changes in water level. When using submersible transmitters in applications where silt or solids are present, it is necessary to choose a transmitter able to tolerate these applications. A transmitter designed for water with solids will have a cover over the diaphragm that allows for easy cleaning, but it is important not to damage the diaphragm when cleaning.

Ultrasonic level instruments

Ultrasonic instruments are another common technology used to measure wet well water level. Ultrasonic instruments operate based on the time of flight (ToF) principle: an acoustic pulse is sent to the surface of the water being measured and reflected back. The time it takes to reach the water and return provides the distance to the water, which is then converted into a level signal. One of the big advantages of ultrasonic level devices is that they are non-contact: the transducer sending the acoustic pulse does not come in contact with the water, providing a cleaner application for sewage wet wells.

However, ultrasonic instruments are also not immune to problems. The humid conditions in a wet well can cause condensation to form on the face of the transducer, which can attenuate the acoustic energy, limiting the range. In some cases, it can even cause a near-field fault. Confusing acoustic reflections caused by structures in the wet well such as ladders, pump columns, cables, etc, must also be taken into consideration and avoided or mapped out if the ultrasonic device being used offers this feature.

Another concern is splashing on the transducer, which can leave residue able to attenuate the acoustic energy, requiring cleaning. In sewage wet wells, where methane can be present, ultrasonic instruments experience another problem: the speed of sound is faster in methane than it is in air. This will cause errors in the level measurement, resulting in the level appearing higher than it actually is.

Radar level measurement

A more recent trend in level measurement for lift station wet wells is the use of radar technology. In the past, radar transmitters were considered too expensive for use in wet wells, but recent developments in electronics have allowed for lower-cost offerings.

Radar transmitters offer a number of advantages over traditional wet well level technologies. First, like the ultrasonic instrument, radar is a non-contact technology using the time of flight measurement principle. With radar, an electromagnetic pulse is directed to the surface of the material being measured and the energy is reflected by the different dielectric constant of the water compared to air. Similar to ultrasonic instruments, the time taken to reach the water surface and the reflection to return are measured, providing a distance to the surface of the water which is then used to calculate the level.

Along with the advantages of non-contact measurement, the transmission of electromagnetic energy is not affected by vapours or steam in the air space above the water, which is a distinct advantage over ultrasonic level technology.

New radar antenna designs provide wetted parts of Teflon with a concave surface. These concave antennas are designed to shed condensation build-up on the antenna face, preventing attenuation of the electromagnetic signal. In sewage wet well applications, the Teflon helps to prevent material from adhering to the antenna when water splashes solids.

When selecting a radar unit for mounting inside a wet well vault it is important to remember the transmitter may experience submersion in extreme conditions. For this reason, selecting an encapsulated transmitter that meets IP68 (protected against temporary immersion) is recommended.

Mapping it out

One of the great advances in new radar units is the simplicity of commissioning and mapping. With all modern radar transmitters, accessing the setup program can be made via Bluetooth and executed on a smart phone or tablet (Figure 2). This is a great advantage over older units that required commissioning through a pushbutton, an HMI interface or opening the housing and connecting a cable to a laptop with a modem.

In many cases the radar transmitter may be located in an installation that is difficult to access. This is particularly true of water and sewage wet wells where the radar may be inside a concrete vault. Trying to reach these units for access to the HMI or to connect a cable to a modem may require a confined space permit. With Bluetooth it is a simple matter of opening the access lid in most cases.

The latest radar technology also offers sophisticated mapping programs that allow the transmitter to ignore internal obstructions such as ladders, pump columns, cables and baffles. While these mapping programs are sophisticated, they are much easier to implement than previous mapping programs from even a few years ago. If the wet well is empty or the level is at its lowest point, simply executing the mapping routine is all that is required. The radar transmitter does all the work. In situations where the tank is not empty, you need to determine where the level is and then map to a few centimetres above the actual level.

Summary

There are a number of ways to measure the water level in lift station wet wells. Selecting the technology able to provide the most reliable level measurement with the least maintenance should be the goal. While traditional technologies, such as submersible hydrostatic and ultrasonic instruments can provide a reliable measurement, the new lower-cost radar transmitters now available in the market should be considered for these applications. The advantages gained in performance and reliability along with the ease of commissioning are significant.

Five common mistakes in industrial temperature monitoring

In industrial production, effective temperature and humidity monitoring is more than just...

Video-based water detection reduces contamination in gas pipeline

How a US midstream company improved gas quality and reduced operating costs.

Aquamonix integrates flow monitoring for major gold producer

Instrumentation company Aquamonix has installed a flow monitoring solution for a major...