The missing middle: Solving the logic solver gap in SIS design

Why safety professionals need a new class of logic solver; one that bridges the enormous gap between safety PLCs and single-loop devices.

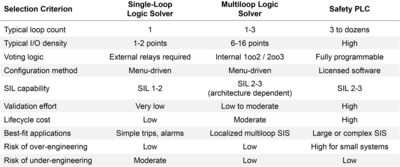

The logic solver is the decision engine of every Safety Instrumented System (SIS). It evaluates process inputs, applies voting logic, and triggers the action that reduces risk. Despite its importance, logic solver selection has long forced engineers into a binary choice: a full safety PLC or a single-loop logic solver, often called an alarm trip.

Both options are proven and widely used, but they were built for very different applications. As a result, many modern SIS designs fall uncomfortably between them, too complex for a single-loop device, yet far too small to justify a safety PLC. This “logic solver gap” has driven unnecessary cost, complexity, and compromise for years. When neither option fits cleanly, engineers are left defending designs that become difficult to justify during hazard reviews, audits, or incident investigations.

The limits of traditional choices

Single-loop logic solvers have improved significantly. Many now offer diagnostics, password protection, configurable logic, and simple commissioning. They are easy to deploy and maintain. Their limitation becomes clear once more than one loop is involved or when voting logic is required. Expanding functionality often means relay inter-wiring and workarounds they were never designed to support.

Safety PLCs sit at the other end of the spectrum. They can easily handle small safety applications, but at a cost. Licensed software, specialised skills, additional documentation, and higher lifecycle expenses are common. For skid-mounted systems, remote assets, temporary facilities, or localised shutdown functions, a safety PLC is often technically capable but operationally inefficient.

What most SIS applications actually look like

In practice, many SIS designs share similar characteristics:

- One to three safety functions

- Modest I/O counts, often 6–16 points

- Simple voting logic such as 1oo2 or 2oo3

- Localised installation on skids or remote units

- Straightforward proof testing requirements

These systems are not trivial, but they rarely justify the overhead of a full safety PLC-based safety platform.

The emergence of the multiloop logic solver

These midrange solvers thrive in places where safety PLCs feel like overkill: pump shutdowns, burner management, wellhead safety, small-scale overpressure protection, tank protection, and localised trip systems. They also integrate exceptionally well with existing BPCS or PLC infrastructures, especially in hybrid safety strategies where a larger safety platform handles core systems, while multiloop logic solvers are deployed at peripheral or isolated SIFs.

Supporting modular and localised safety

SIS architectures are increasingly modular. Instead of routing all safety logic through a central system, many facilities deploy localised safety nodes dedicated to specific hazards.

By keeping voting and trip decisions local, multiloop logic solvers reduce wiring, speed commissioning, and simplify proof testing. With fewer components and interfaces, validation is easier and changes require less rework; an advantage that aligns well with IEC 61511 lifecycle expectations.

Integration without compromising independence

Modern multiloop logic solvers also provide visibility through read-only interfaces such as Modbus, Ethernet diagnostics, or HART passthrough. This allows safety status and device health to be monitored without compromising the independence of the safety function.

Completing the logic solver spectrum

Multiloop logic solvers do not replace safety PLCs or single-loop devices. They complete the logic solver spectrum by providing a practical, right-sized option for applications that have long been underserved. For engineers focused on defensible designs, manageable complexity, and systems aligned with real risk, the missing middle is no longer optional, it is becoming essential.

The Machinery Regulation will be mandatory in less than a year — are you ready?

The EU Machinery Regulation and the Cyber Resilience Act will reshape how manufacturers and...

Pilz delivers compliant access management system at Schüco's testing facility

Schüco envisioned a centralised permissions management system that would streamline access...

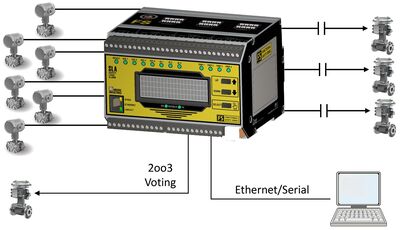

High Integrity Pressure Protection System (HIPPS) 2oo3 voting shutdown system

The Moore Industries SLA Multiloop and Multifunctional Logic Solver plays a pivotal role in...