ABB releases AI-enabled robotic item picker

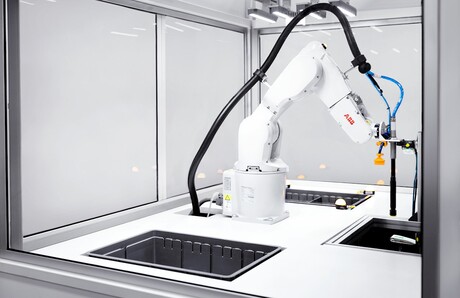

ABB Robotics has announced the launch of the Robotic Item Picker — a new AI- and vision-based solution that ABB said can accurately detect and pick items in unstructured environments in warehouses and fulfilment centres.

“The explosion of e-commerce, changing consumer demands and global labour shortages are driving the need for flexible automated solutions that make order fulfilment and distribution faster and more efficient,” said Daniel Navarro, managing director of Consumer Segments and Service Robotics at ABB Robotics. “With its ability to learn and adapt in constantly changing warehouse environments, our AI-enabled Robotic Item Picker sees items and decides how to pick them, at speed with more than 99.5% efficiency, helping businesses overcome these challenges and build resilience.”

Using machine vision and artificial intelligence, the item picker system determines the optimal grasp points for each item before the suction gripper picks up and places the item into designated bins. The system does not require any human supervision or information about the physical attributes of the items it picks.

Featuring a robot, suction grippers and a proprietary machine vision software, the Robotic Item Picker is designed to fully automate complex picking and placing tasks for a range of items including cuboids, cylinders, pouches, boxes, polybags and blister packs, which otherwise require the dexterity and flexibility of humans.

Suitable for a range of loads and applications, the Robotic Item Picker can be fitted to one of three ABB robots: the IRB1200, IRB 1300, and IRB 2600. With a payload of up to 3 kg and a reach of up to 1.65 m, the Item Picker can achieve a picking rate of up to 1400 items per hour.

“The Item Picker is controlled by an easy-to-use application software that seamlessly integrates all parts of the system, and interacts with other peripheral equipment, enabling customers and partners to easily add components and other functionalities,” Navarro said. “ABB also offers a suite of services for the entire package, including service agreements, online training, preventive maintenance and technical online support.”

IFR predicts the top five global robotics trends for 2026

The International Federation of Robotics has predicted the top five trends for the robotics...

ARM Hub to launch Propel-AIR 2.0 with robotics showcase

Federal Minister for Industry and Science Tim Ayres will officially launch the...

Advantech partners with D3 Embedded on AMR sensing and computing

Advantech has announced a partnership with D3 Embedded to offer an integrated sensing and compute...