Harnessing generative AI for predictive maintenance

Generative AI can play a transformative role in predictive maintenance by providing deeper insights and advanced solutions.

Artificial intelligence (AI) has revolutionised various industries by enhancing efficiency and optimising processes. A key area where AI demonstrates significant potential is factory maintenance. Through their use in predictive maintenance, AI systems can anticipate and prevent machinery breakdowns, thereby reducing downtime and operational costs. In addition, the latest advancements in generative AI (GenAI) have made it easier than ever for factories to streamline their operations and overcome the daily challenges that prevent organisations reaching optimal efficiency.

Challenges faced by maintenance teams

Maintenance teams encounter numerous challenges that hinder their efficiency. Many team members are not data scientists and often struggle to interpret complex data, particularly when pressed for time or without access to expert guidance. Language barriers and the retirement of experienced engineers exacerbate the problem, leading to a loss of critical knowledge. Furthermore, the skills shortage and frequent job changes among the younger workforce make retaining and sharing knowledge increasingly difficult. Data is often inaccessible or difficult to reference, creating barriers to collaboration across multiple locations.

How generative AI addresses the challenges

GenAI addresses maintenance challenges by simplifying workflows and enhancing decision-making processes. It eliminates the need for team members to be data scientists, as the AI provides clear, actionable insights. Its user-friendly interface allows staff to ask questions directly, enabling quick, informed maintenance decisions.

Generative AI can play a transformative role in predictive maintenance, as large language models (LLMs) are designed to embed expert knowledge and provide insights based on vast datasets. Their impact can be broken down into two key areas:

- Expert knowledge integration: GenAI systems integrate extensive domain knowledge from reliability engineering and condition monitoring to provide detailed diagnostic insights. These AI models can process large volumes of historical records (and time series data in the future) to identify patterns and predict failures with minimal human intervention.

-

Scalable solutions: By automating data analysis and diagnosis, GenAI enables predictive maintenance solutions to scale across multiple assets and industries.

GenAI is revolutionising predictive maintenance, addressing traditional challenges and paving the way for innovative solutions in the industry.

The intersection of GenAI and predictive maintenance

GenAI based on large language models – like ChatGPT – plays a significant role in understanding and processing textual data, which has traditionally been a challenge for machine learning and statistical techniques focused on numerical data, such as time series data from sensors. However, textual information often holds valuable insights into maintenance practices. This ability to derive meaningful information from minimal text input is beneficial, given that maintenance records are typically brief and lacking detail.

Leveraging minimal data for maximum impact

A common concern among organisations is the perceived lack of data to benefit from AI-driven predictive maintenance. However, even small amounts of data or brief maintenance records can provide substantial insights. Many organisations have a wealth of data within their controllers and existing systems that can be utilised effectively. The key is to harness this data, even if it is minimal, to start building an understanding of machine conditions and failure modes.

GenAI has proven impressive in its ability to infer detailed information from limited text. This means that organisations do not need to overhaul their maintenance processes or produce extensive reports for every maintenance ticket. Short and concise descriptions can be sufficient for AI to surface valuable knowledge and provide actionable insights.

Practical applications and benefits

The practical applications of generative AI in predictive maintenance are vast. One of the primary benefits is the ability to enhance prescriptive maintenance and knowledge capture. When a maintenance case is raised, AI can provide evidence and prescriptive guidance based on historical data patterns and past cases.

This includes potential root causes and recommended actions, with links to historical cases for further reference. This approach ensures that maintenance staff have access to relevant information without needing to sift through extensive records manually.

Prescriptive maintenance

This aspect of AI involves providing actionable recommendations based on data analysis. For instance, when a sensor detects an anomaly, AI can correlate this data with past cases, identify potential causes, and suggest specific maintenance actions. This process reduces downtime and prevents minor issues from escalating into major problems.

Knowledge capture

AI can help in capturing and organising institutional knowledge, which is crucial as experienced technicians retire. By analysing maintenance records, AI can identify common issues and effective solutions, creating a repository of knowledge that can be accessed by less experienced staff.

Virtual maintenance assistance

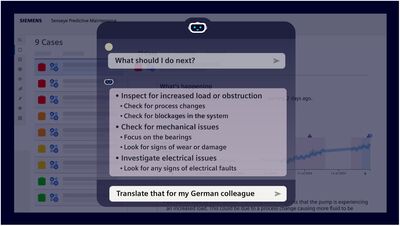

GenAI-powered virtual maintenance assistance tools help teams make better-informed maintenance decisions by using data to form in-depth knowledge of assets, provide instant answers to questions and retain all knowledge forever.

Virtual maintenance assistance tools can also potentially translate information into multiple languages and consolidate the knowledge of all maintenance staff. Capturing learnings as part of a team’s everyday workflow, they become an additional expert team member and a single source of truth — as well as learning and referencing all data sources, surfacing information when needed and bringing colleagues into the conversation seamlessly.

The future of conversational functionalities

One of the latest developments in generative AI within predictive maintenance is conversational functionality integrated into PdM platforms. This feature will allow users to make ad hoc queries in natural language, enabling them to ask for summaries of maintenance activities or other specific information about an asset. The AI copilot will gather and summarise this information, making it easier for users to get the insights they need without navigating through multiple screens and records.

In the longer term, research is being conducted on applying the fundamental technologies of large language models to time series data. This approach shows promise in enhancing anomaly detection and forecasting, potentially leading to more accurate and reliable predictive maintenance systems.

Enhanced anomaly detection

By applying language model techniques to time series data, AI can improve its ability to detect anomalies. This involves not just recognising when data deviates from the norm but understanding the context and likely causes of such deviations. This can lead to faster and more accurate diagnoses of potential issues.

Advanced forecasting

AI can also enhance forecasting capabilities, predicting when a machine is likely to require maintenance based on historical data and current operating conditions. This proactive approach allows for better planning and resource allocation, ultimately leading to more efficient operations.

Implications for sustainability

Sustainability in predictive maintenance extends beyond immediate operational benefits to encompass broader environmental and resource management goals:

- Upstream and downstream impacts: Predictive maintenance can help minimise waste throughout the entire supply chain, from production processes to product disposal.

- Resource efficiency: By optimising maintenance schedules and reducing equipment failures, predictive maintenance helps conserve resources and reduce the environmental impact of manufacturing processes.

-

Remote monitoring: Digital and cloud-based solutions enable remote monitoring of equipment, reducing the need for onsite inspections and lowering the carbon footprint associated with maintenance activities.

Predictive maintenance, driven by advanced data analytics and AI technologies, represents a significant step forward in both operational efficiency and sustainability. By leveraging time series data, condition indicators and generative AI, businesses can achieve more accurate predictions, reduce downtime and support environmental sustainability.

Ensuring security and privacy

One critical aspect of integrating generative AI into predictive maintenance is addressing security and privacy concerns. Organisations are justifiably worried about their data being inadvertently exposed or used inappropriately. To mitigate these concerns, AI systems can be configured to operate within a secure cloud environment, where learning is turned off to prevent data from being shared or used outside the organisation.

Another layer of security involves anonymising data before it is processed by AI. This means removing or obfuscating personally identifiable information and other sensitive details, reducing the risk of data breaches.

Regulatory considerations

As AI technologies become more prevalent, regulatory frameworks are essential to ensure their responsible use. Key regulatory considerations include:

- Transparency and accountability: Ensuring that AI-generated insights are clear and understandable, with transparency about the sources of data and the limitations of AI recommendations.

- Human oversight: AI systems should support human decision-making rather than replace it. Clear guidelines are necessary for how humans should interpret and act on AI-generated insights.

- Ethical use of data: Regulations must ensure that data is used ethically and responsibly, protecting user privacy and ensuring that AI systems are not misused for harmful purposes.

A radical shift

Generative AI is set to bring a radical shift in how predictive maintenance is conducted. By leveraging AI’s ability to process and understand both numerical and textual data, organisations can gain deeper insights and more effectively maintain their assets.

The focus on delivering value, ensuring security and maintaining usability will drive the successful integration of AI into predictive maintenance systems, ultimately leading to more efficient and reliable operations.

The future of predictive maintenance lies in the seamless integration of generative AI, which promises not only to enhance current practices but also to open new avenues for innovation and efficiency. As organisations continue to explore and adopt these technologies, the landscape of maintenance will undoubtedly evolve, bringing about a new era of precision and reliability in industrial operations.

Cyber risk is rising faster than Australian manufacturers can respond

Protecting manufacturing environments requires a multi-layered approach that addresses...

The environmental impact of AI: a help or hindrance for industry?

AI offers powerful tools to improve sustainability in water, waste and energy systems, but its...

Securing industrial networks: three architecture strategies

The goal of industrial cybersecurity is to enhance existing architectures with layered, pragmatic...