Gantry crane weighing systems with Interface wireless load pins

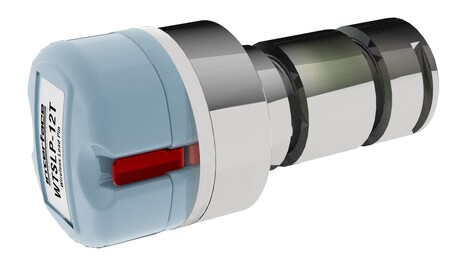

Interface Wireless Load Pins are designed to directly replace existing load-bearing pins in a crane’s header block, providing a signal proportional to the measured load.

Gantry cranes are essential for various mobile and lifting applications in industrial and construction environments. A reliable weighing system is crucial to ensure the crane can safely handle heavy containers or loads, preventing failures and accidents.

A load pin, which often replaces a standard clevis or pivot pin, is a strain gauge sensor that measures the force applied across the device. The strain gauges are installed within a small bore through the centre of the pin. Interface load pins have been used in a wide variety of projects across many industries.

Load pins are a simple, but highly powerful sensor that provides data collection for accurate and frequent measurement. The load pin can replace a bolt, clevis, sheave, and an equaliser pin, as well as other load-bearing components to measure tensile and compression forces.

Machined from high tensile stainless steel, Interface load pins are suitable for exposed situations including seawater. Interface offer standard sizes of load pins between 500 kg to 1500 MT, and they are custom manufactured to meet specific dimensional requirements for each application.

The most commonly referenced applications for load pins are for overhead equipment like cranes and lifts. Through ingenuity of engineers and our customers, load pins are rapidly expanding in popularity for infrastructure, aerospace, maritime, agriculture, and industrial use cases. The load pins of today are used to test and measure force, load, and weight in a much larger variety of applications. They are also growing in demands due to their wireless capabilities for both short and long distances. This includes uses not only for cranes and lifting devices, as well as construction equipment, industrial machines, nautical craft and equipment, aerospace structural environments, and civil engineering applications.

Interface offers a range of sensor options for crane weighing and overload protection systems. These systems assist operators by providing real-time total weight data, preventing overload situations. Interface engineering experts has decades of experience delivering measurement solutions for these systems, which have been installed in all types of hoists and cranes, including overhead travelling cranes, construction cranes, infrastructure project cranes, shipyard and port cranes, as well as marine and offshore cranes.

Interface Wireless Load Pins are designed to directly replace existing load-bearing pins in a crane’s header block, providing a signal proportional to the measured load without requiring any modifications to the crane. This allows the crane weighing and overload system to alert the operator of potential lifting hazards and assist with safe load management. Pre-set audible and visual alarms can also be integrated, along with triggers to shut down the crane if a lift exceeds the safe load limit.

Interface has a great deal of experience supplying ruggedised and standard use load pins for testing. The load pins are in high demand in the infrastructure industry not only due to their accuracy and reliability, but also due to the fact that Interface offer a myriad of communication channels through both wired and wireless solutions. As requirements are made to repair and rebuild public infrastructure resilience, equity, and safety for all users are key criteria in design and build stages. This is where Interface load pins are key to the solution, for durability, accuracy, quality, and ease of use.

For demanding environments such as oil rigs and FPSOs, Interface can supply ATEX- and IECEx-certified measurement sensors with both explosion-proof (Ex d) and intrinsically safe (Ex i) approvals. Interface also offer below-hook solutions for situations where permanent installation is not required or where using a load measuring pin isn’t feasible.

Explosion-proof liquid analyser for hazardous areas

The ECD explosion-proof liquid analyser for hazardous areas measures specific ions, pH, ORP, DO...

Reducing emissions from industrial processes by effective particulate monitoring

Continuous particulate monitoring instruments play an important role in air pollution control.

How to optimise WWTP flow measurement for process efficiency

In wastewater treatment plants, the right flow measurement instrumentation ensures optimal...