Collaboration on automotive repair robotics announced

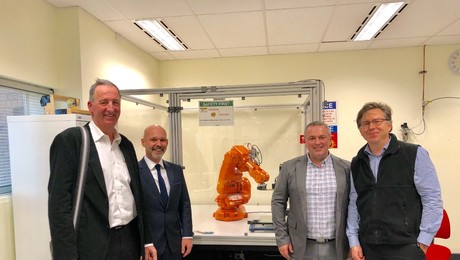

AMA/Gemini Group, Australia’s largest automotive collision repair network, has thrown its weight behind Industry 4.0 innovator Tradiebot Industries’ Repair-bot project being developed in conjunction with Swinburne University.

With backing from the Australian Government’s Innovative Manufacturing Cooperative Research Centre (IMCRC), the stage one, $1.2 million collaborative Repair-bot project is making use of 3D printing technologies and robotics along with novel materials to enable automated rapid repair service for plastic car parts.

“Commitment from leading industry players such as the AMA/Gemini Group is a positive indication we are on track in solving current obstacles in the automotive collision repair industry around the repairs of plastic components,” said Tradiebot Industries Founder Mario Dimovski.

“We look forward to building our relationship with the AMA/Gemini Group as we work together towards developing new technologies, skills, materials and complex automated collision repair systems.”

“With advances in vehicle technology, parts costs rising and skills availability ever challenging, we are constantly looking at ways to advance the industry, refine our operation and continually deliver on our ability to provide value to our clients and customers,” said Dave Calder, Corporate General Manager, AMA/Gemini Group. “Innovation is core to our business and we are delighted to be collaborating with the leaders in this space, Tradiebot Industries and Swinburne University.

“The research and development of augmented repair processing, 3D printing, robotics and the advancement in industry 4.0 technologies is a perfect fit and positive outputs of our collaboration will generate immense value to the automotive repair industry.”

“The Swinburne research team is excited to welcome AMA/Gemini as a collaborator on the Repair-bot project with Tradiebot Industries,” said Dr Mats Isaksson, Swinburne University of Technology. “My team and I look forward to the added industry expertise that David Calder and his team will offer.

“This sector is highly concentrated and ferociously competitive, so a solution like the Repair-bot has the potential to be truly transformational, using Industry 4.0 technologies to reduce material wastage, ease the pain of ever more complex and restrictive design elements, and take on routine tasks in an increasingly tightly skilled labour market.”

As well as improving procedures in the automotive repair industry, the collaboration is a further sign that the $7 billion Australian industry has started down the path of digital transformation, with technologies that have the potential to lead the world.

IFR predicts the top five global robotics trends for 2026

The International Federation of Robotics has predicted the top five trends for the robotics...

ARM Hub to launch Propel-AIR 2.0 with robotics showcase

Federal Minister for Industry and Science Tim Ayres will officially launch the...

Advantech partners with D3 Embedded on AMR sensing and computing

Advantech has announced a partnership with D3 Embedded to offer an integrated sensing and compute...