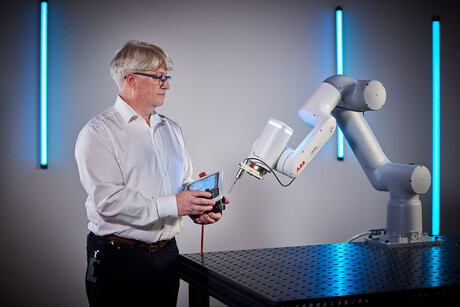

ABB launches Ultra Accuracy for GoFa cobots

ABB Robotics has launched a feature for its GoFa collaborative robots called Ultra Accuracy. Designed to provide the highest level of precision available, ABB claims the Ultra Accuracy feature provides over 10 times greater path accuracy that other cobots, with path accuracy down to 0.03 mm across the entire workspace and absolute position accuracy of 0.1 mm.

As industries look to automation to enhance product quality and achieve tighter tolerances — continuously decreasing the maximum allowable deviation from the standard in quality control — there is a growing need for robots that can perform tasks with exceptional precision. By combining ultra-accurate path performance with the simplicity, safety and flexibility of a cobot, ABB says its Ultra Accuracy feature opens a wide range of possibilities for the use of cobots in businesses including electronics, automotive, aerospace and metal fabrication.

Ultra Accuracy meets the demands of applications where exact positioning is crucial for maintaining product quality and operational efficiency. Applications include gluing and sealing in consumer electronics production, laser welding of car parts, composite material layers in aerospace manufacturing, and precision laser cutting in metals fabrication processes. It can also be used for accurate positioning of additive layers in building prototypes in 3D printing, and for performing precision quality checking in metrology applications.

Additional benefits include the combination of precision with speed and a full range of motion. Unlike conventional 2D gantry systems traditionally used in electronics manufacturing, GoFa cobots offer full 6D motion across their entire workspace without requiring additional calibration work, providing the flexibility and mobility to handle a broader range of tasks.

ABB adds that the combination of Ultra Accuracy and RobotStudio enables the programming of applications offline, with a 99% match between the simulation and reality, eliminating the need for touch-ups and guaranteeing precise and efficient implementation.

IFR releases position paper on AI in robotics

The International Federation of Robotics has released a position paper that examines how...

IFR predicts the top five global robotics trends for 2026

The International Federation of Robotics has predicted the top five trends for the robotics...

ARM Hub to launch Propel-AIR 2.0 with robotics showcase

Federal Minister for Industry and Science Tim Ayres will officially launch the...