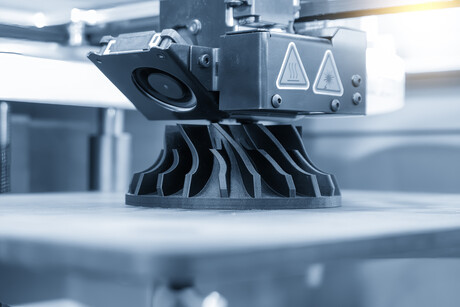

Using AI to trace the origins of 3D-printed parts

Researchers at the University of Illinois Urbana-Champaign have developed an artificial intelligence system that can pinpoint the origin of 3D printed parts down to the specific machine that made them.

The technology could allow manufacturers to monitor their suppliers and manage their supply chains, detecting early problems and verifying that suppliers are following agreed upon processes.

A team of researchers led by Bill King, a professor of mechanical science and engineering at the university, has discovered that parts made by additive manufacturing carry a unique signature from the specific machine that fabricated them. This inspired the development of an AI system that detects the signature, or ‘fingerprint’, from a photograph of the part and identifies its origin.

“We are still amazed that this works: we can print the same part design on two identical machines — same model, same process settings, same material — and each machine leaves a unique fingerprint that the AI model can trace back to the machine,” King said. “It’s possible to determine exactly where and how something was made. You don’t have to take your supplier’s word on anything.”

The results of this study were recently published in the Nature partner journal Advanced Manufacturing.

The technology has major implications for supplier management and quality control, according to King. When a manufacturer contracts a supplier to produce parts for a product, the supplier typically agrees to adhere to a specific set of machines, processes, and factory procedures and not to make any changes without permission. However, this provision is difficult to enforce. Suppliers often make changes without notice, from the fabrication process to the materials used. They are normally benign, but they can also cause major issues in the final product.

“Modern supply chains are based on trust,” King said. “There’s due diligence in the form of audits and site tours at the start of the relationship, but for most companies it’s not feasible to continuously monitor their suppliers. Changes to the manufacturing process can go unnoticed for a long time, and you don’t find out until a bad batch of products is made.

“Everyone who works in manufacturing has a story about a supplier that changed something without permission and caused a serious problem.”

While studying the repeatability of 3D printers, King’s research group noticed that the tolerances of part dimensions were correlated with individual machines. This inspired the researchers to examine photographs of the parts. It turned out that it is possible to determine the specific machine made the part, the fabrication process, and the materials used: the production fingerprint.

“These manufacturing fingerprints have been hiding in plain sight,” King said. “There are thousands of 3D printers in the world, and tens of millions of 3D printed parts used in airplanes, automobiles, medical devices, consumer products, and a host of other applications. Each one of these parts has a unique signature that can be detected using AI.”

“Our results suggest that the AI model can make accurate predictions when trained with as few as 10 parts,” King said. “Using just a few samples from a supplier, it’s possible to verify everything that they deliver thereafter.”

Australian Vanadium partners with Sumitomo on Kalgoorlie battery bid

Australian Vanadium has announced that its subsidiary, VSUN Energy, has entered into a pre-bid...

Investment in large-scale renewables surging ahead: report

The latest quarterly report from the Clean Energy Council finds that more renewables powered up...

NSW renewables workforce receives $15m government investment

The NSW and federal governments are investing $15 million over four years into skilled...