Partnership to build the future of Australian manufacturing

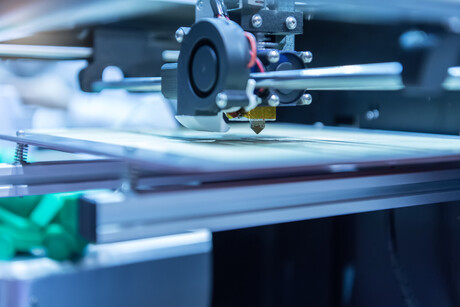

Additive manufacturing is transforming industries by using 3D printing to rapidly create customised products one layer at a time. The global market for this booming manufacturing process has been projected to reach US$84 billion by 2030.

At the University of Technology Sydney (UTS), researchers are making digital blueprints for the future of a manufacturing industry that is being revolutionised by 3D printing.

Now, a $270 million partnership between universities, industry and government — the Additive Manufacturing Cooperative Research Centre (AMCRC) — will position Australia as a leader in the burgeoning technology.

“Over the past decade, additive manufacturing has seen remarkable growth. Advancements in 3D printing technologies are now being used in full-scale commercial production, transforming industrial processes and supply chains. We’re entering a new era in efficient and sustainable manufacturing,” said Simon Marriott, Director of the AMCRC.

UTS is among the 14 research partners in the AMCRC, which is building a national additive manufacturing ecosystem using 3D printing to transform industry sectors including defence, aerospace, health care, automotive and construction.

Experts in the UTS Centre for Advanced Manufacturing and UTS Rapido will be working with industry partners on digitisation and AI platforms to help optimise additive manufacturing processes.

Professor Jochen Deuse, Director of the Centre for Advanced Manufacturing, will lead research on digital twins, which allow for the virtual representation of physical objects that is critical to accurate 3D printing.

“Through the AMCRC, we’re striving to bring the materials, processes and machines used in additive manufacturing technologies to a higher level of technological maturity. Digitisation and AI will play a critical role in doing that,” he said. “Our research aims to develop a new type of blueprint for digital twins that enables the simultaneous production of parts in additive manufacturing processes, and supports the seamless integration of design, planning, data management and shopfloor engineering processes.”

Herve Harvard is Executive Director of the research and development innovation hub UTS Rapido, which will be developing AI tools to support additive manufacturing.

“AI tools are also critical to optimising additive manufacturing processes. Our experts in UTS Rapido will work with industry partners to develop an AI platform that helps people and machines work together,” he said. “This platform will provide quality assurance of additive manufacturing processes by incorporating domain knowledge. The team will also explore supervised and unsupervised learning problems, as well as reinforcement learning methods for advanced process controls.”

The AMCRC has been boosted by an injection of $57.5 million in Australian Government funding. This will be on top of contributions by industry partners and universities worth more than $200 million over the next seven years.

Mineral resources stocktake reinforces Australia's strengths

The latest Geoscience Australia stocktake of mineral resources has reinforced Australia's...

Engineers Australia reflects on World Engineering Day 2026

Engineers Australia says that World Engineering Day on 4 March shines a global spotlight on how...

SPC Global to close facility in Vic under demand-led strategy

SPC Global plans to close its Mill Park facility in Victoria by August 2026 and...