Livium and UoM partner on microwave technology for REE extraction

Livium Ltd has announced it has signed a non-binding term sheet with the University of Melbourne (UoM) to explore the use of the UoM’s microwave technology for the extraction of rare earth elements (REE) to complement its core recycling business. Livium and UoM are now working towards execution of a binding IP licensing agreement that will give Livium exclusive worldwide rights to commercialise the technology for the next 20 years.

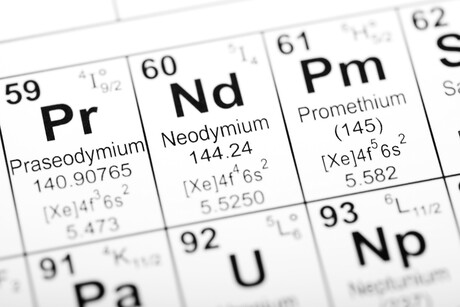

A collection of 16 metallic elements found together on the periodic table are known as rare earths. This group comprises the 15 lanthanides in addition to yttrium. The recovery and repurposing of these sought-after elements from discarded items, including permanent magnets, electric motors and electronic refuse, is called REE extraction. Magnets containing these materials are crucial to the shift towards clean energy, as they are integral components in electric vehicle propulsion motors and wind turbine generators.

Worldwide demand for REE magnets has almost doubled, climbing to 93 kilotons between 2015 and 2023.1 REE recycling is still a largely untapped market, given currently only about 1% of REE are being recycled.2 This presents a huge adjacent commercial opportunity for Livium with the global addressable market for REE expected to reach US$7.3 billion by 2026.

Microwave heating is a promising solution for replacing traditional methods of REE extraction due to its efficient, rapid and sustainable heating transmission. Where traditional methods extract REE by acid leaching, solvent extraction and ion-exchange processes, microwave technology can enhance chemical reactions and alter the morphology of minerals, which is key to selectively recovering rare earth elements, as well as other valuable metals such as copper, gold, vanadium and platinum group metals (PGMs) from metallurgical wastes.

Studies at UoM to date have found that microwave technology can deliver high recovery rates at low energy consumption levels, with an estimated 85% reduction of energy consumption relative to ‘Hot Block’ digestion technologies.

Recovery rates of greater than 95% for neodymium (Nd) and greater than 80% for praseodymium (Pr) have been achieved in laboratory test work, with potential to achieve greater than 90% Pr with an oxidant.

Livium has a strategic focus on expanding its recycling capabilities into adjacent circular economy opportunities, a plan initially announced in June. The company’s priority is to apply its core competencies into strategic adjacencies such as REE and solar recycling, as well as black mass processing.

“We are excited to partner with the University of Melbourne and leverage their innovative microwave technology to explore how we can extract rare earth elements,” said Livium CEO and Managing Director Simon Linge. “This is a significant step in our strategy to broaden our recycling capabilities and meet the growing global demand for REEs.

“Securing exclusive access to this REE technology will allow us to expand our commercial offering, further cementing our leadership in resource recovery and process innovation.”

1. International Energy Agency (IEA) 2025, Global Critical Minerals Outlook 2025

2. Zadeh J 2025, ‘Rare Earth Elements in Trade and Tariffs: Geopolitical Implications 2025’, Discovery Alert

Australian researchers create graphene from peanut waste

UNSW Sydney engineers have developed a cheaper and greener way to make graphene from leftover...

Banksia Minerals gets $5m for critical energy mineral processing

Australian startup Banksia Minerals has received $5m in funding from ARENA for its...

CSIRO opens $3m upgrade to renewable energy lab

CSIRO's $3 million upgrade to its energy lab provides new capacity for researchers and...