Additive manufacturing unlocks power for space and defence missions

An Australian-led additive manufacturing research project is set to transform how long-duration space and defence missions are powered, overcoming one of the most persistent barriers facing operations in space, subsea and extreme environments: reliable, maintenance-free energy.

Through its first funded research project, the Additive Manufacturing Cooperative Research Centre (AMCRC) is helping South Australian nuclear engineering and technology company entX transition its GenX Betavoltaic Power Generator prototype to pre-commercial manufacture.

Developed in collaboration with Adelaide University, GenX is a next-generation nuclear battery that combines additive manufacturing and advanced surface engineering to deliver what the developers say is unprecedented power density in an ultra-compact form.

Traditional power sources struggle to provide continuous energy where maintenance, refuelling or solar access is impractical — such as on spacecraft, unmanned underwater vehicles and remote defence surveillance systems.

“Reliable, long-life power is one of the biggest bottlenecks facing space, subsea and defence systems,” said Dr Scott Edwards, entX General Manager, Space and Defence. “GenX fundamentally changes what’s possible. By re-engineering betavoltaics as ultra-thin, additively manufactured devices, we’re achieving power densities that were previously out of reach and enabling entirely new mission profiles.”

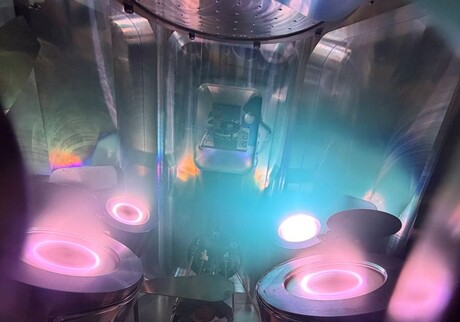

At the core of GenX is a novel manufacturing process that integrates additive manufacturing with advanced coating and thin-film deposition, blurring the traditional boundaries between surface engineering and 3D printing.

Nanoscale metal, metal-oxide and semiconductor layers are deposited sequentially to build complex functional architectures layer by layer, resulting in ultra-thin betavoltaic films that exceed current global performance benchmarks.

“This is not an incremental improvement — it’s a genuine step-change,” said Professor Drew Evans, who helped develop the GenX prototype and will lead the research project at Adelaide University. “By combining novel semiconductor deposition methods with additive manufacturing and surface engineering, we’ve demonstrated betavoltaic devices with power densities that simply weren’t achievable using conventional approaches.”

Over the next 14 months, entX and Adelaide University will validate both the GenX device and its manufacturing process to prepare for customer evaluation.

Additive manufacturing will also rapidly prototype radiation-shield encasements that ensure safe integration into space, defence and remote systems.

“This $1.8 million project is a clear example of how additive manufacturing can take breakthrough research and make it manufacturable at scale,” said Simon Marriott, Managing Director of the Additive Manufacturing CRC.

Mineral resources stocktake reinforces Australia's strengths

The latest Geoscience Australia stocktake of mineral resources has reinforced Australia's...

Engineers Australia reflects on World Engineering Day 2026

Engineers Australia says that World Engineering Day on 4 March shines a global spotlight on how...

SPC Global to close facility in Vic under demand-led strategy

SPC Global plans to close its Mill Park facility in Victoria by August 2026 and...