Performance without compromise: enhancing manufacturing quality with single-controller solutions

By Dennis Wylie, Principal Product Manager, Rockwell Automation

Tuesday, 28 October, 2025

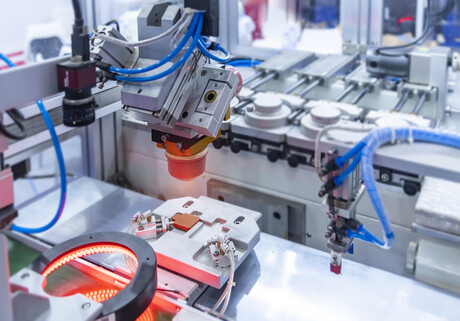

You've probably had the experience of visiting a contemporary factory floor and being amazed by all the incredible robots, sensors and machines working like a finely choreographed dance. It's quite remarkable — until there's a malfunction. And therein is something that has been frustrating quality engineers for decades.

Here's the situation: most of these operations have three or four different control systems that, historically, barely talk to each other. It's like trying to conduct an orchestra where the violin, brass, and percussion sections all have different sheet music. Maybe it works most of the time, but when quality issues crop up? Good luck figuring out what went wrong and where. The real problem we're all wrestling with is that manufacturing has become so complex because, frankly, it had to. Customers want customised products delivered faster than ever, with zero defects.

However, this is where chaos can start.

Most organisations have been managing this complexity by piling on more systems. Need motion control? There's a controller for that. Safety monitoring? Another controller. Process control? Yep, another one. It's a bit like having several project managers for the same project: chaos waiting to happen.

Whenever those systems need to share information, there's a delay. And when it comes to manufacturing, delays equal quality problems. If your motion controller is on one clock and your safety system is on another, tiny timing differences can create big quality problems.

Think of it like buying an iPhone. Say you chose the 128 GB model. At first, it works great, but over time as you download more apps and take more family photos, you run out of space. Your phone is slower, more RAM is used, and you might have to offload apps to regain acceptable functionality. Then you really wish you planned ahead and bought the 256 or even the 512 GB version.

Another analogy: If you're trying to fill bottles on a high-speed line, and your filling system is not precisely synchronised with your capping system because they're on different controllers, you're in trouble. Some of the bottles will be overfilled, others underfilled, and some won't be capped correctly at all.

The industry has recognised the problems. 2024 data published by the US National Association of Manufacturers (NAM) reports that "an overwhelming majority of manufacturers (86%) believe that the effective use of manufacturing data will be 'essential' to their competitiveness. But to realise data's potential, manufacturers must figure out how to organise and analyse their data effectively, ensure that their data is trustworthy and align their business strategy closely with their data strategy."

Furthermore, the NAM report also identified the main data integration challenges for manufacturers being data that comes from different systems or in different formats (53%), data that is not easy to access (28%) and the lack of internal skills to analyse data effectively (28%).

Similar challenges exist in Australia, with AI Group's Technology Adoption in Australian Industry survey showing a strong majority of manufacturers are actively adopting new technologies, but many cite financial risk, interoperability concerns, and regulatory uncertainty as major constraints on adoption.

Why everything's changing now

The good news? The control systems world has finally caught up with what we actually need. We're not talking about incremental improvements here but fundamental performance and efficiency improvements.

New controllers are incredibly fast. We're talking scan times that will make older systems look like they're in slow motion. And they can handle large applications while still maintaining safety functions at pace even when everything else is maxed out.

Here's what gets me really excited: these newer controllers have multiple processor cores that can do different things simultaneously. So, one core would be handling your motion control, another one would be running diagnostics, and a third one would be handling communications. No more waiting in line, no more bottlenecks that degrade your quality. But the real game-changer? It's all integrated from the ground up. Safety, security, communications — it's all in there. No longer will you wrestle with trying to get discrete systems to play nicely together.

Futureproofing

In today's industrial landscape, compliance is a moving target with rules on safety, cybersecurity and the environment constantly evolving. Single-controller solutions help businesses stay ahead by providing data-driven ESG insights on energy use, emissions and materials. This makes it easier to meet emerging regulations and show a real commitment to responsible operations.

For Australian manufacturers, these systems also make it easier to meet WHS compliance, cybersecurity requirements under the Australian Cyber Security Strategy, and new sustainability and ESG reporting frameworks that demand accurate, auditable data.

What this really means for your production line

Below are some concrete examples of why this is important:

1. Precision at scale

Do you recall when more than 500 axes of motion control used to be unimaginable? Now it's the norm.

I was at a semiconductor factory last month and they are performing hundreds of highly coordinated moves in parallel. The positional precision that they are realising would have been impossible with several controllers attempting to coordinate via a network.

2. Real-time everything

You can now easily connect more than 600 Ethernet devices to a single controller. That gives you the ability to deploy quality sensors everywhere without slowing your system down. Real-time statistical process control calculations are performed right at the controller level, so you can make adjustments before issues of minor variation become major problems.

3. Safety that actually helps quality

When safety and quality systems are integrated, they can work together instead of against each other. If a quality sensor detects something wrong, the safety system can shut things down immediately — no communication delays, no "wait, let me check with the other controller" nonsense.

4. Reduced redundancy

Moving to one integrated system converts redundancy from a decentralised, less efficient model to a centralised, intelligent one. Instead of redundant functionality being duplicated across numerous standalone controllers with redundant backup facilities, communication links, and failover mechanisms, an integrated system can have smart coordinated redundancy with shared backup facilities and failover enabled by full system knowledge. This consolidation eliminates the overcomplication of having to cope with multiple schemes of redundancy that compete with or interfere with each other but permitting more advanced redundancy mechanisms such as dynamic load balancing, predictive failover, and centralised health monitoring.

The coordinated approach also disposes of the risk of cascade failures that can occur when multiple independent systems having independent redundancy logic attempt to coordinate upon fault incidents and enables more cost-effective redundancy since the redundant resources may be dynamically allocated according to real-time priority rather than statically reserved for independent controllers.

The business case that actually makes sense

Consolidation from a quality management perspective has tangible benefits far greater than the upfront cost considerations. There are a number of reasons for this:

1. Smart quality decisions in real time

These new controllers can run AI and analytics right on the factory floor. Tasks like pattern recognition, predictive analytics and adaptive control are things that would have otherwise meant sending data to the cloud and waiting for feedback. For apps where you're measuring quality in milliseconds, this is huge.

2. Less complexity, fewer headaches

Managing one system instead of four isn't just easier — it's much more reliable. Your techs gain expertise on one stage instead of struggling to manage multiple specialised systems. Training is easier, troubleshooting is faster, and your team can focus on actually improving processes instead of just trying to get systems to talk to each other.

3. Data you can actually trust

When all your quality data comes from one place, you can be certain that it's all correctly timestamped and correlated. That's especially important in regulated industries where audit trails and traceability are not just nice-to-have features — they're essential.

4. Faster problem-solving

When there is an issue (and let's be real, there is always an issue), you have only one place to look instead of four. Modern diagnostics give you an overview of what's going on in your whole system. Root cause analysis is straightforward instead of an exercise in detective work.

5. Better security

Cybersecurity risks are real, and quality systems are an increasing target because their compromise has immediate business impact. One controller means one security perimeter to protect instead of four, which is much simpler and much safer.

The trade-offs (because nothing's perfect)

As with most things in life, for all the benefits, there are trade-offs. Specialised controllers can squeeze a little more performance out of narrow uses. But this is the thing: integration's quality benefits almost always overshadow these small performance differences.

The biggest challenge is usually dealing with legacy systems. You can't just rip everything out and start from scratch. Would that it was that easy, right? But you can chart a phased migration that maintains quality while progressively upgrading capabilities.

Where this is all heading

If you're in pharma production, aerospace, medical devices, or any other industry where quality failures are catastrophic, this technology is a game-changer. The more demanding your quality requirements, the more you'll benefit from consolidation. Also, if you're confronted with legacy systems that are becoming maintenance nightmares or can't handle new quality requirements, controller consolidation often provides features simply not available before.

The future is very promising. Software-defined automation enables seamless expansion of disciplines without modifying hardware — imagine upgrading or patching independently from control systems, much like adding new apps to a smartphone.

We're also seeing IT and operational technology converging, so real-time quality dashboards, predictive analytics, and automated reporting are becoming standard. And with all the new sustainability and traceability requirements on the horizon, having integrated data capture isn't just a nicety — it's more of a necessity.

The bottom line

If you're thinking about control architectures, start with your quality requirements. Work your way backward from there. Unified controllers in this day and age offer quality that multi-controller setups simply can't match.

The question isn't whether or not dedicated controllers can be matched by these new systems — generally, they're exceeded. The question is whether or not you can afford the quality compromises of fragmented architectures.

Manufacturing quality demands just keep increasing, and single-controller systems are not just keeping up — they're setting new benchmarks. It's not a question of choosing a control architecture; it's a question of choosing a platform for long-term quality excellence.

We are rapidly moving toward a future where you choose the functions, features and the capacity you want, and the appropriate package will be put together.

Once you see what integrated control can do to your quality figures, you'll wonder how we ever thought multiple controllers were a good idea in the first place.

Virtual PLCs — a big step forward!

It looks as though the days of PLCs running a single control task, on dedicated hardware, using a...

Open Process Automation: how and where to start

Open Process Automation presents a transformative opportunity for enterprises seeking to...

Seeing with AI: flexible navigation in dynamic environments with Visual SLAM

Automation solutions based on camera vision and AI models overcome the limitations of existing...