UNSW researchers to scale up development of clean aviation fuel

UNSW researchers have been granted $1.2 million from the TRaCE Lab to Market Fund to help them scale up a next-generation electrolyser system that helps produce sustainable aviation fuel (SAF) using renewable energy.

The electrolyser converts carbon dioxide and water into precursors that can then ultimately be turned into green fuel for aircraft.

The funding from TRaCE, the Trailblazer for Recycling and Clean Energy program established by the Australian Department of Education, has been boosted by industry partners to total $4.2 million, with the aim of achieving a critical breakthrough in the reduction of emissions in aviation.

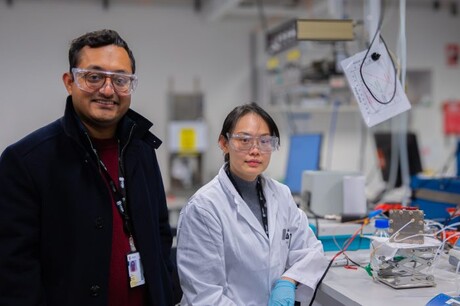

The UNSW-led project, involving Dr Rahman Daiyan, Scientia Professor Rose Amal and Adjunct Professor Jimmy Yun, will work in association with Australian partner Tjindu Power and Chuangqi Times (Qingdao) Technology Company, a cleantech developer based in China.

The team has already developed a carbon dioxide electrolyser system using low-cost transition metal and carbon catalysts, which can be integrated with the well-established Fischer–Tropsch process to produce sustainable aviation fuel.

Decarbonising aviation is one of the toughest challenges in the race to net zero. Unlike cars or homes, planes can’t easily switch to being electrified and the fuels they burn release large amounts of carbon dioxide into the atmosphere. Globally, aviation accounts for about 2–3% of emissions, but it’s a fast-growing sector with limited alternatives.

Many emerging clean energy technologies aim to replace fossil fuel production with sustainable aviation fuels and e-fuels, but these solutions are still expensive, energy-intensive and not yet ready for mass deployment.

“Our goal is to revolutionise how we produce clean fuels for aviation, using renewable energy to transform CO2 into usable fuels without requiring costly infrastructure changes,” Daiyan said. “This technology could be the key to decarbonising aviation, one of the world’s most challenging sectors.”

The grant from TRaCE will help to move the technology from TRL 4 (proof of concept in the lab) to TRL 6 (validated prototype in a relevant environment). A spin-out company, Gurung Fuel, led by the industry partners, has been created to lead commercialisation, stakeholder engagement and capital raising.

“This partnership is a major step towards scaling the cutting-edge electrolyser technology,” said Yun, from Chuangqi Times (Qingdao). “We’re not just developing a solution; we are creating a game changer for the aviation industry, with the potential to make a global impact.”

The research project is a strategic opportunity for Australia, which is facing a critical challenge in its fuel security.

Currently, the nation holds only 48 days’ worth of fuel reserves — far below the 90 days required by international standards. The nation’s heavy reliance on imported fuel also makes it vulnerable to global disruptions and recent geopolitical crises have underscored the urgent need for a sustainable and self-sufficient solution.

NSW renewables workforce receives $15m government investment

The NSW and federal governments are investing $15 million over four years into skilled...

Gilmour Space opens office in South Australia

Gilmour Space Technologies has opened an office at the Lot Fourteen innovation precinct to...

Fortescue commissions first battery electric locomotives

Fortescue has announced that it has commenced commissioning of two new battery electric...