UNSW and Siemens collaborate on recycling research

Siemens has announced that it has signed a research agreement with the University of New South Wales (UNSW) to assess the feasibility and economic viability of recycling epoxy mouldings with embedded metallic components that are used in Siemens-manufactured medium voltage switchgear.

The agreement will focus on moving switchgear recycling towards a circular model where materials are recovered to become feedstock for remanufacturing and other uses. Currently, there are limited recycling capabilities for epoxy mould components worldwide, with most approaches focused on retrieving the embedded copper while the rest of the epoxy materials are sent to landfill.

The study will explore the application of novel microrecycling science and technology developed by the UNSW Sustainable Materials Research and Technology (SMaRT) Centre. The SMaRT Centre can recover and re-form materials from complex waste streams, and has commercialised some of its MICROfactorie Technologies.

In this project, SMaRT will embark on one of the first initiatives globally to examine the recycling potential of this critical material used in energy infrastructure, representing a significant step towards creating more sustainable solutions for high-performance composites. The team aims to develop methods to recover the epoxy materials with the aim of creating reusability pathways for raw resin components.

The study will also explore the potential economic value of these recovered materials, and examine environmental impacts incurred through the process as part of a lifecycle assessment. The findings will provide a foundation for future research and the potential development of an industrial-scale recycling plant for this type of waste.

“The rapid energy transition and increasing demand for electricity over the last few decades has in turn led to unprecedented demand for medium voltage switchgear. As we look at long-term business, economic and societal sustainability and how we decarbonise, it’s clear that we need to explore every avenue, especially when it comes to decarbonisation,” said Brett Watson, Head of Electrification and Automation business for Siemens in Australia and New Zealand. “At the same time, we need to be mindful of avoiding the unintended consequences of energy transition. Enabling a circular economy that explores how we minimise waste and increase resource efficiency is a critical part of this.”

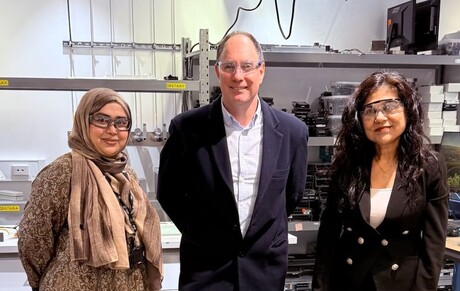

Epoxy moulding recycling is a complicated process as each moulding is specific to the products it has been designed for, with its own chemical and metallic composition. The research was funded through a fellowship awarded to Dr Rumana Hossain, a lecturer and researcher at the UNSW SMaRT Centre in Sydney, under the Trailblazer for Recycling and Clean Energy (TRaCE) program — a Commonwealth-supported and part-funded initiative by UNSW and the University of Newcastle aimed at realising Australia’s potential as a global clean energy superpower.

Professor Veena Sahajwalla, Director of the UNSW SMaRT Centre, welcomed the collaboration.

“Using ‘waste as a resource’ to build the components and infrastructure needed to electrify our communities is really the only effective safe and sustainable solution to create a truly sustainable future,” she said. “Developing green materials opportunities like this for Australia would help to create new jobs, along with other economic, social and environmental benefits.

“It gives me great pride to lead a team of people doing valuable research into materials circularity, helping breathe new life into old products and waste that would otherwise go into landfill. The work we do here is not just significant for Australia in our fight to decarbonise and become more resource efficient but also helps steer global innovation.

“Siemens is a global leader in switchgear technology, so it only seems fitting that we work with them to explore the potential of reusing the materials in epoxy mouldings. It’s great to collaborate with a company that is genuinely interested in scaling sustainable impact for future generations.”

Mineral resources stocktake reinforces Australia's strengths

The latest Geoscience Australia stocktake of mineral resources has reinforced Australia's...

Engineers Australia reflects on World Engineering Day 2026

Engineers Australia says that World Engineering Day on 4 March shines a global spotlight on how...

SPC Global to close facility in Vic under demand-led strategy

SPC Global plans to close its Mill Park facility in Victoria by August 2026 and...