Digital twins allow plants to be emulated before investing

Committing to a new factory setup or production process is often a significant investment. Once machinery is installed, it can be difficult to adjust the plant layout if new efficiencies are discovered or if new issues come to light.

But what if you could first see the entire setup virtually, and test how well it works, tweak certain parts and optimise performance before installing the physical plant? Or train operators before the plant actually exists, expediting time to market?

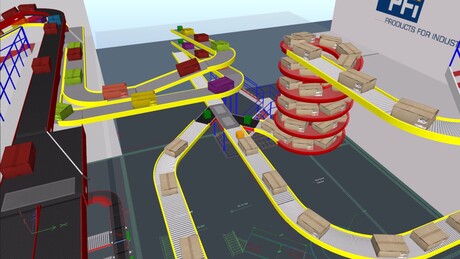

Rockwell Automation said its Emulate3D digital twin software is designed to achieve these goals, and it was one of the future-focused technologies on display at the recent ROKLive automation event in Sydney.

ROKLive was attended by more than 450 industry professionals, including Rockwell Automation client Products For Industry, which ran a session on how Emulate3D is helping to provide its customers with additional certainty, and reduced risk by completely visualising a new or upgraded plant, prior to the physical implementation.

Rockwell Automation Regional Director, South Pacific, Anthony Wong said systems such as Emulate3D help manufacturers look into the future before committing heavy capital. He said the system provides accurate simulation models to improve systems planning and decision-making. It allows emulation trials that evaluate the whole machine, including the control system and associated production, before commissioning begins.

“By using 3D CAD modelling and integrated automation software, users can test the entire production process virtually, which helps mitigate risk and increases cost-efficiencies,” he said. “Once people see and test technology such as Emulate3D it removes a lot of the anxiety about where and how to invest. Manufacturers understand they need to make the jump into smart manufacturing — our recent Plex State of Smart Manufacturing report, which surveyed more than 300 companies, showed that many companies are not sure which way to jump.”

Emulate3D Global Business Development Manager Tyler Phillips also attended ROKLive Sydney, and commented that automation is expanding in Australia and New Zealand. “As automation becomes increasingly commonplace, technologies like Emulate3D can validate business decisions early in the process — because it can be expensive to be wrong.”

Digital twin software enables users to see how their machine runs before parts are ordered, and to discover controls issues before going onsite. It enables users to transport plant personnel to a virtual world where they can train on systems without downside consequence, predict future performance and simulate line changes.

Aspen Technology introduces CCUS planning solution

AspenTech Strategic Planning for Sustainability Pathways is designed to enable users to optimise...

AVEVA collaborates with Microsoft on industrial AI assistant

AVEVA's industrial AI assistant, running on Microsoft Azure OpenAI Service, is designed to be...

Hexagon and Dragos announce technical partnership on OT cybersecurity

The technical partnership will focus on integrating the OT cybersecurity capabilities of the...