Innovation beyond the ISO standard

ISO standards are important benchmarks for industrial products, but sometimes it is necessary to go beyond the standard to create devices that meet the real needs of the application. Standards are undoubtedly valuable and set important industry benchmarks and controls; however, they don’t always the deliver the best product solution.

Designers and manufacturers often have to think outside the box; therefore, it is often important to look beyond ISO standards to realise product development excellence and, ultimately, leading industrial solutions. ISO (International Organization for Standardization) is an independent non-governmental organisation which publishes standards that cover almost every industry and has a membership of 163 national bodies. To date, the organisation has published more than 21,000 standards and related documents covering a myriad of industries and applications.

ISO standards must in some cases be set aside when they don’t address the requirements of an application or exclude important criteria crucial to the design process. Trying to conform to a standard can compromise the design or process requirements and, ultimately, the final product.

ISO sometimes falls short due to the sheer scope of industries and standards it has to cover. That’s why it comes down to fully understanding the application of a product and then designing it to be as safe and efficient as possible.

For example, in the food and beverage sector hygiene is paramount, and the resultant ISO standards place it at the top of the priority list. However, ISO standards for pneumatic valve and cylinder design in particular don’t specify hygienic design — which means manufacturers could miss out on important criteria if they follow the standards to the letter.

In an extremely competitive environment where cost of ownership, energy efficiency, safety and functionality are key concerns, the use of technology improvements and innovative features that go beyond ISO standards must be considered.

The perception is that ISO-compliant products are safe, readily available and cost competitive, and can be interchanged with other brands. Also, industry players believe they mitigate the risk of developing orphaned products if they meet the necessary standards. This isn’t necessarily true: products should be developed to deliver optimal features and performance and not just tick all the industry standard boxes.

Ask your supplier about engineering products around your applications. Your supplier should be able to provide you with the correct selection of components and offer options and solutions that meet your application requirements. Customers are not made to fit into catalogues, but catalogues should be built around customers. Services also exist where a supplier can make the selections for the customer — for example, help you to swap out old technology for newer, or choose the correct ISO product or ISO replacement product. By assisting their customers in selecting the new standard product replacement, suppliers can assist their customers in realising large improvements in operating efficiency.

Products which are not necessarily ISO compliant but which exceed ISO specifications are sometimes available. These could solve many of the end user’s problems, such as clean design; various connector options; rubber and metal seal options; lighter weight; and a dustproof or splashproof design.

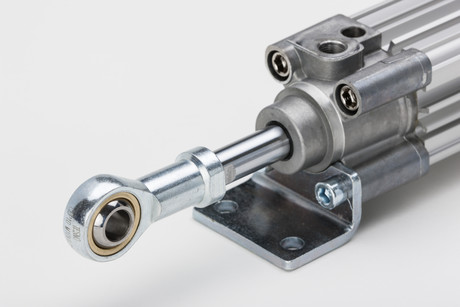

Alternatively, look out for products which meet the relevant ISO standard but can be modified to fit into the application. This approach provides users with the freedom to choose the best product for each application. In the case of cylinders, for example, it allows customers to meet specific machine requirements in areas like piston rod modifications; cylinder mounting modifications; corrosion-resistant design; barrel, end cap and porting modifications; and additional rod wiper solutions.

While standards provide a minimum quality and feature set that everyone making a particular product must comply with, standards-based solutions are not always the most suitable for the application. Suppliers that can provide ‘better than standard’ products, or that can modify the product to suit the application, should be well considered for the best results.

Australia must rethink the foundations of industrial automation

In order to compete globally, we need a willingness to rethink the foundations and build...

IMARC 2025 turns up the innovation spotlight

IMARC 2025 will bring mine owners, operators and contractors together with a line-up of the...

Skills are more critical than ever in today’s AI world

Our increasing reliance on AI to offload cognitive tasks weakens our memorising systems and skills.