Image analysis system detects failures and deviations in frontline worker activities

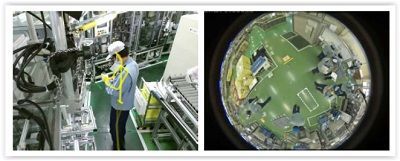

Hitachi, in collaboration with Daicel Corporation, has developed an image analysis system that supports quality improvements and increased productivity by detecting signs of operational failures in production line facilities and deviations in worker activities on the front lines of manufacturing.

For 16 months, starting in February 2015, Hitachi and Daicel have been conducting joint verification tests aimed at the practical application of the image analysis system at Daicel’s Harima Plant (Tatsuno City, Hyogo Prefecture), which manufactures core components for airbags. As a result of these tests, the image analysis system is expected to be able to dramatically improve the in-process guarantee rate for products through a transition from ‘representative point management’ in quality assurance based on lots to ‘all point management’ (continuous monitoring of the status of man, machine and material) based on individual product serial numbers.

Furthermore, by shifting the role of on-site management supervisors from a focus on ‘after the fact’ measures to the monitoring of trends and preventive measures using obtained image data, they will tie these activities into the prevention of failures before they occur.

Hitachi and Daicel will begin operations of the image analysis system at the Harima Plant in FY2016 and plan to promote rollout to six of Daicel’s main overseas plants.

In recent years, mega recalls in various industries have brought about a renewed awareness of the importance of accumulating and managing manufacturing performance data to identify the causes of product defects and to implement countermeasures. In the advanced manufacturing workplaces of the future, it will be necessary to gather a wide range of work-related performance data, including manufacturing performance and inspection data and the results of visual checks by workers. It aims to reach new traceability by establishing mutual links among these different forms of product performance data. All of these will be achieved by introducing new manufacturing execution systems that incorporate IoT technologies.

Hitachi and Daicel studied manufacturing performance data at the Harima Plant from the perspectives of ‘3M’ — man, machine and material — and examined ways of tying the results of these studies into the fourth M — methods — in order to create new production innovation methods. By quantitatively determining the status of machines, materials and worker activities on the front lines of manufacturing, it was determined that this approach is effective in improving product quality and in increasing productivity and the accuracy of traceability.

Recently, based on the expertise in production innovations cultivated at the Harima Plant, Hitachi and Daicel developed an image analysis system that supports improvements in quality and productivity as well as the rapid discovery of defects in machines and materials. It also supports deviations in worker activities by analysing surveillance videos on the front lines of manufacturing using Hitachi’s image analysis technologies and conducted joint verification tests of this system.

The image analysis system uses depth cameras to extract 3D forms in order to measure worker activities from the 3M perspective and obtains positional information on human joints, such as hands, elbows and shoulders. Then, based on frontline interviews and observations, it derives standard behaviour models that exclude information not directly related to tasks (eg, the length of arms and legs). Furthermore, it identifies deviations in worker activities by using statistical comparisons with those standard behaviour models.

The system also detects abnormalities, in the case of defects in materials and facilities, by analysing differences compared to video images under normal conditions. In addition, the system is able to detect abnormalities in the case of welding defects by combining voltage and current data from existing facilities with light-emitting element colour analysis using high-speed cameras.

In this way, the system quickly extracts only information related to improvements in quality and productivity from huge volumes of video data. It combines this function with data analysis to improve work efficiency and quality stabilisation and to quickly discover defects. By accumulating image data and connecting final products based on individual product serial numbers, the image analysis system can detect production processes which cause defected products and improve them. When inappropriate operation is detected, it can trace final products based on serial numbers, thus achieving multitraceability.

In the future, starting at the Harima Plant, Hitachi and Daicel plan to install the image analysis system at six overseas plants and aim to construct a globally integrated management system by aggregating and analysing information via a cloud service. Hitachi will make the image analysis system available to the manufacturing industry worldwide by applying ideas and technologies of the IoT platform ‘Lumada’.

Claroty appoints Wavelink as sole distributor for entire Australian business

Wavelink has announced that cybersecurity solutions company Claroty has awarded Wavelink the sole...

Nozomi Networks extends partnership with Yokogawa

Nozomi Networks OT and IoT visibility and threat detection capabilities are now part of...

Nozomi Networks secures funding from Mitsubishi and Schneider Electric

Nozomi Networks has secured $100 million to accelerate OT cyber-defence technology.