ABB acquires pioneer in 3D inspection technology

ABB has acquired Spanish start-up company NUB3D, a leading innovator of digital, 3D inspection and quality-control solutions.

The acquisition expands the group’s portfolio of ABB Ability solutions that connect customers to the Industrial Internet of Things. ABB Ability builds on the intelligent cloud, using connected devices to generate actionable digital information for a broad range of customers. The two companies have agreed not to disclose the value of the transaction.

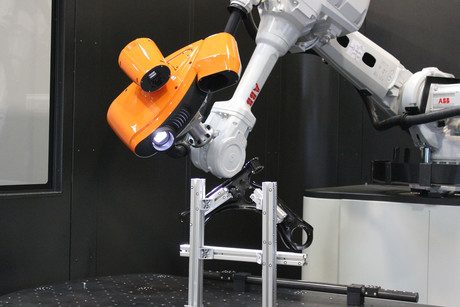

NUB3D is a privately owned company headquartered in Barcelona. It supplies 3D white-light scanning sensor technologies, using digital scans to optimise inspection and quality assurance in manufacturing. The sensors can detect defects on a manufactured part with an extremely high level of accuracy.

By combining NUB3D’s 3D vision and metrology with ABB’s brand, worldwide reach and customer support, ABB will be able to create automated turnkey inspection and quality control systems for automotive original equipment manufacturers, aerospace companies and customers in other sectors such as metals and plastics.

The technology represents the future of flexible manufacturing, enabling a high level of automation with advanced data analysis that can be used to optimise production processes. NUB3D will become part of the Robotics business of ABB’s Robotics and Motion division and the new global application centre for 3D metrology in ABB.

“With this acquisition we are moving a step closer to the factory of the future. As our customers’ automation processes become more advanced and production cycles shorten, the ability to efficiently automate quality inspections becomes a compelling competitive advantage,” said Sami Atiya, president of ABB’s Robotics and Motion division. “Combining robotics and software is pivotal in implementing digitalisation and expanding ABB Ability as a key driver of our Next Level strategy.”

Manufacturers increasingly have to improve quality and productivity while accommodating greater product variation and customisation in smaller lots. NUB3D’s 3D sensor technology rapidly records and compares highly detailed geometric and surface data with digital CAD models, enabling the automation of inspection of manufactured parts and pieces, helping factories to reduce cycle times while raising quality and reducing the risk of quality control errors.

Jorge Rodriguez, CEO of NUB3D, added: “This is the perfect time and ABB is the perfect partner for us to accelerate our expansion into the growing 3D metrology market. The ABB Ability platform perfectly complements our use of cutting-edge digital solutions, and ABB’s leading robotics portfolio and vast global footprint will ensure that we can make the most of our early-mover advantage in integrated robotic inspection solutions.”

ABB and NUB3D have already successfully introduced two fully robotised automatic quality inspection solutions for offline and inline inspection using NUB3D’s 3D white-light sensors. They are marketed under the names FlexInspect and InspectPack.

Researchers develop new robot collision avoidance algorithm

Faster and more accurate than some alternatives, this new approach could be useful for robots...

Cognex launches 3D vision system with AI

AI-powered 3D vision system offers fast deployment and more reliable inspections for...

Teradyne Robotics partners with NVIDIA to add AI to robots

A new collaboration with NVIDIA adds accelerated computing to robotics, increasing the...